-

Company

Guanhong Intelligence was founded in 2009, with industry-leading intelligent logistics and intelligent equipment, mastering the integrated solutions for intelligent logistics equipment, intelligent equipment systems and their core components R & D, design, production integration capabilities; the company has a strong R & D team consisting of PhDs, masters and senior engineers, who have a wealth of experience and expertise in the field of intelligent equipment.

-

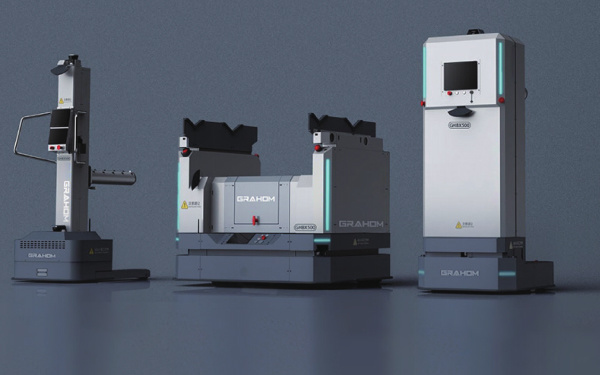

Product

Guanhong Intelligence was founded in 2009, with industry-leading intelligent logistics and intelligent equipment, mastering the integrated solutions for intelligent logistics equipment, intelligent equipment systems and their core components R & D, design, production integration capabilities; the company has a strong R & D team consisting of PhDs, masters and senior engineers, who have a wealth of experience and expertise in the field of intelligent equipment.

-

Solution

Guanhong Intelligence was founded in 2009, with industry-leading intelligent logistics and intelligent equipment, mastering the integrated solutions for intelligent logistics equipment, intelligent equipment systems and their core components R & D, design, production integration capabilities; the company has a strong R & D team consisting of PhDs, masters and senior engineers, who have a wealth of experience and expertise in the field of intelligent equipment.-

New energy lithium battery industry

-

Printing and Packaging Industry

-

Optical Film/Diaphragm/Polarizer Film Industry

-

-

-

-

Power industry (interrupters, transformers)

-

-

-

-

Service

Guanhong Intelligence was founded in 2009, with industry-leading intelligent logistics and intelligent equipment, mastering the integrated solutions for intelligent logistics equipment, intelligent equipment systems and their core components R & D, design, production integration capabilities; the company has a strong R & D team consisting of PhDs, masters and senior engineers, who have a wealth of experience and expertise in the field of intelligent equipment.

-

News

Guanhong Intelligence was founded in 2009, with industry-leading intelligent logistics and intelligent equipment, mastering the integrated solutions for intelligent logistics equipment, intelligent equipment systems and their core components R & D, design, production integration capabilities; the company has a strong R & D team consisting of PhDs, masters and senior engineers, who have a wealth of experience and expertise in the field of intelligent equipment.

-

Contact

Guanhong Intelligence was founded in 2009, with industry-leading intelligent logistics and intelligent equipment, mastering the integrated solutions for intelligent logistics equipment, intelligent equipment systems and their core components R & D, design, production integration capabilities; the company has a strong R & D team consisting of PhDs, masters and senior engineers, who have a wealth of experience and expertise in the field of intelligent equipment.

AGVs For Connecting Wafers

E-maill:

key word: AGVs For Connecting Wafers

Product Inquiry ➜Summarize

The Wand AGV (Automated Guided Vehicle) is a state-of-the-art automated guided vehicle designed for high-precision material handling of wafers.In the modern manufacturing industry, especially in high-tech industries such as semiconductor, photovoltaic and other fields, the application of AGV is becoming more and more extensive.

Core Features

1. accurate positioning: advanced navigation technology, such as laser navigation, visual navigation, etc., to achieve accurate positioning of the crystal bars, to ensure the smooth progress of the production process.

2. High-efficiency handling: AGV can automatically complete the handling task of the wafers, which greatly saves the labor cost and improves the production efficiency.

3. Intelligent scheduling: through the intelligent scheduling system, it can realize the cooperative operation of multiple AGVs, optimize the production process and improve the overall efficiency of the production line.

4. Flexible Configuration: AGV can be flexibly configured according to the production demand, adapting to different production environments and production scale.

Application Scenario

AGVs are mainly used in the production lines of semiconductor and photovoltaic industries for the automatic handling, storage and management of wafers.During the production process, the AGVs can accurately deliver the wafers to the designated position according to the preset routes and instructions, ensuring the continuity and efficiency of the production line.

Technical Advantages

1. Improve production efficiency: the automated operation of AGV greatly reduces manual intervention and improves the operational efficiency of the production line.

2. Reduce the error rate: through accurate positioning and intelligent scheduling, AGV can reduce the error rate during the handling of wafers.

3. Cost saving: AGV can reduce the human resource cost of the enterprise and improve the competitiveness of the enterprise.

4. High flexibility: AGV can be flexibly configured according to the production demand, adapting to different production environments and production scale.

Future Development

With the continuous development of science and technology, the technology of baton AGV is also progressing.In the future, AGV will be more intelligent and automated, with stronger environment perception and autonomous decision-making ability.At the same time, with the development of Internet of Things, big data and other technologies, AGV will achieve closer integration with other equipment in the production line to improve the overall efficiency and intelligence of the production line.

Product Inquiry

Contact Information

Suzhou Headquarters:No. 500, Chunfeng Road, Huangdai Town, Xiangcheng District, Suzhou City

Telephone:0512-69216006

Copyright © Suzhou Guanhong Intelligent Equipment Co., Ltd.