New Energy lithium Battery Industry

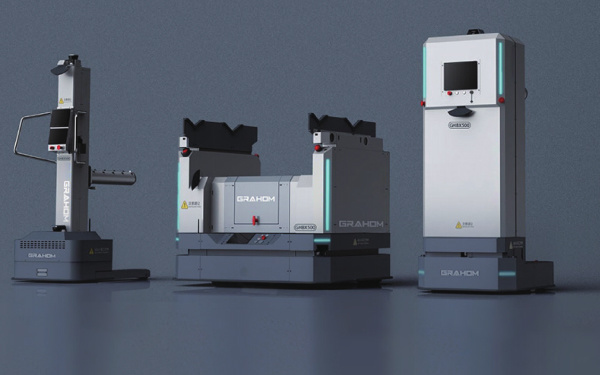

Guanhong new energy lithium industry intelligent system solutions, to provide customers with film roll handling robots [high-precision lifting AGV, high-precision cantilever axis AGV, automatic cantilever trolley], general-purpose form of robots [backpack handling AGV, stacking AGV, side insertion handling robot, ground cattle handling robot, balanced weight handling robot] and other forms of robots, lithium electrician to build a productionManufacturing new era, customized intelligent logistics solutions, to achieve the goal of transparent factories.Guanhong has a stable software intelligent scheduling system, and MES, WMS system seamless connection, help the factory orderly and efficient manufacturing.

Printing And Packaging Industry

The pre-press process includes design layout and plate making; the post-press process covers die-cutting, hot stamping/silver stamping, laminating, varnishing, creasing, etc.; and the assembly and inspection are in order, including assembly, quality inspection and packaging.The right part focuses on the introduction of the printing and packaging industry, comparing traditional printing and packaging with intelligent printing and packaging.The traditional mode of production efficiency varies from person to person, quality control is difficult, cumbersome and long preparation time and other problems; while the intelligent printing and packaging under the assistance of Guanhong Intelligent has the advantages of high production efficiency, accurate quality control, cost optimization, short preparation time and other advantages, and can achieve rapid response effect.

Optical Film/Diaphragm/Polarizer Film Industry

Smart factory solutions are significantly used in the optical film/diaphragm/polarizer film industry.By introducing intelligent technology, this industry is able to automate, digitize and intelligentize the production process.Smart factory solutions can monitor production data in real time, optimize production processes, and improve production efficiency and product quality.In addition, through intelligent analysis and forecasting, companies can accurately control costs, optimize inventory management, and improve market competitiveness.At the same time, smart factory can also help the industry to respond to market changes, meet individualized needs and promote product innovation.In short, the application of smart factory solutions will help the optical film/separator/polarizer film industry's continuous development and technological upgrading.

Smart factory solutions are significantly applied in the copper foil industry.Through the introduction of advanced information technology and intelligent equipment, the copper foil production process is automated and intelligently managed.The smart factory solution can optimize the production process and improve production efficiency, while reducing energy consumption and costs.In addition, the intelligent monitoring system monitors the status of equipment in real time, prevents malfunctions and ensures the stable operation of the production line.Intelligent data analysis helps optimize the use of raw materials and reduce waste.The application of environmental monitoring systems ensures that production meets environmental standards.In short, the smart factory solution brings a new situation of production intelligence, management refinement and efficiency maximization for the copper foil industry.

Smart factory solutions are significantly used in the photovoltaic industry.By integrating intelligent technologies, smart factories can optimize PV production processes and improve production efficiency.For example, data analysis and monitoring are utilized to achieve efficient utilization of PV materials and cost control.In addition, intelligent equipment and systems can monitor the production environment in real time to ensure product quality and safety.With the help of IoT technology, it realizes the interconnection and intercommunication among equipments and improves the intelligent level of production line.Smart factory can also help PV enterprises realize green production and reduce energy consumption and emissions.In short, the application of smart factory solutions for the photovoltaic industry has brought about a double enhancement of production efficiency and economic benefits.

The Smart Factory solution is significantly used in the textile industry.By integrating intelligent technologies, the solution helps textile companies to automate, digitize and intelligentize their production processes.Specifically, the smart factory can monitor production data in real time, optimize material management, improve production efficiency and reduce costs.In addition, with intelligent analytics and forecasting capabilities, companies can make accurate decisions and respond quickly to market changes.Through the integration of intelligent textile machinery and equipment, the interconnection between equipment is realized, and the overall production level is improved.In short, the smart factory solution for the textile industry to bring intelligent transformation, help enterprises to enhance competitiveness.

Power Industry (interrupters, transformers)

Smart factory solutions are significantly used in the power industry, especially in the manufacture of interrupters and transformers.Through the introduction of intelligent technology, fine management and control of the production process can be realized.For example, the use of IoT technology, real-time monitoring of the production data of the interrupter and transformer, to achieve intelligent adjustment and optimization of the production process.In addition, big data analysis and artificial intelligence technology can be applied to product quality detection and analysis, improving product quality and production efficiency.The application of smart factory solutions not only improves the manufacturing level of power equipment, but also provides strong support for the sustainable development of the power industry.Through intelligent upgrading, the power industry will usher in a broader development prospect.

The smart factory solution is significantly used in the carbon fiber industry.By integrating intelligent technology, the solution can optimize the carbon fiber production process and achieve fine management.Using Internet of Things (IoT) technology, it can monitor the production environment and equipment status in real time to ensure production safety and improve efficiency.Data analysis and mining technologies help optimize material ratios and production processes to improve product quality.In addition, the smart factory solution can help realize green production and reduce energy consumption and emissions.In short, the application of smart factory solutions will promote technological innovation, industrial upgrading and sustainable development of the carbon fiber industry.

The application of smart factory solutions in the nuclear industry is crucial.By integrating technologies such as IoT, big data and artificial intelligence, smart factories can realize the digitalization and intelligence of nuclear industry production.For example, it monitors the status of equipment in real time, warns of potential safety hazards, optimizes production processes, and improves efficiency and safety.In addition, smart factories can support supply chain management, environmental monitoring and personnel training in the nuclear industry.In short, the application of smart factory solutions helps the nuclear industry to realize efficient, safe and sustainable development and enhance the competitiveness of the nuclear industry.